The air preheaters of a furnace - also called cowpers - are three or four in number and have continuous operation, like the furnace. At an increase of 100 degrees Celsius of the air blown by them, we obtain an increase in the productivity of the furnace and a decrease in the consumption of coke which reduces by a few euros the manufacturing price of a ton of cast iron.

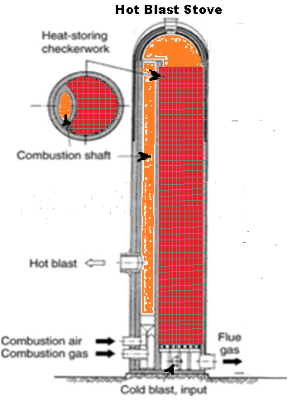

The performance of the cowpers is given first of all by their main constituent element, the regenerator. This is a structure of refractory material of the order of thousands of tons, made up of hundreds of thousands of similar chequer bricks whose vertical gaps form by joining and superimposing continuous channels through which hot gases and cold air circulate alternatively.

Since the invention of cowpers (William Cowper – 1860), the circulation of gases through their generators has been exclusively vertical.

In the mid 1990s in Galati – Romania a generator was experimented where 41% of the vertical channels of each chequer brick were connected within the structure through horizontal channels. The purpose was to uniformize the circulation, increase the heat transfer surface, as well as the vortex and the reliability of the generator. If the last objective was achieved, the others were achieved only partially and only at the top section of the generator, by reducing the consequences due to the eddies created in the dome, a problem that is present today in all cowpers with combustion chamber mounted separately, internally or externally.This has been reported since 1965 by the german Herbert Boenecke (Dusseldorf) in a study published at an Austrian symposium.*

The technical expertise executed in 1994 in Galati by the Bucharest Matallurgical Research Institute for a cowper of an 1000 cubic meters furnace, found an increase in the technological efficiency of the new type of regenerator – in a calculation after the substraction from the thermal balances of the heat losses through the jacket and cooling technological water - of aproximatelly 5.5%.* At that time, the savings obtained from the supply of the cowper correspond to an increase of 48 degrees C of the hot air blown. This increase is compared against the other two cowpers working in the same system, all three cowpers using the same mass and and refractory properties, but with 20% increase in the thermal transfer surface and a partial horizontal air circulation at the new one. The solution was applied to a classic chequer, presented here in "comparison" chapter at the "another exemple" paragraph (the new model was without the horizontal internal channels). That solution has spread worldwide through the initiative of USX (a subsidiary of US Steel) and Mittal Steel through contracts with the author* and is found in various patents: Japan-2854985, U.S.A.-5,924,477, MEX.-203745, U.E.- EP.0832406B1, EP.1925897, etc.

The present technical solution is clearly superior in all aspects, as it appears from the content of the new patent as well as from the adjacent materials.

* documentation accessible on request